Linear feeders play an essential role in the manufacturing process. They are used to accumulate and convey oriented parts from a feeder bowl into downstream equipment. Hoosier Feeder Company offers customers several types of linear feeders.

Here are four key types with details about their use to help you determine the one that’s right for your project:

Vibratory Inline Feeder Systems:

A vibratory inline feeder system uses vibration to transport parts. Inline feeders use multiple track materials, including stainless steel and A2 tool steel, to ensure maximum durability. They also support multiple lines of feed. Vibratory inline feeders are the most commonly used linear feeders and ordered primarily in the automotive and pharmaceutical industries. They have a lower cost and can handle complex parts. The downsides of a vibratory inline feeder system are the noise produced by the inline driver and their limited speed capability versus alternatives.

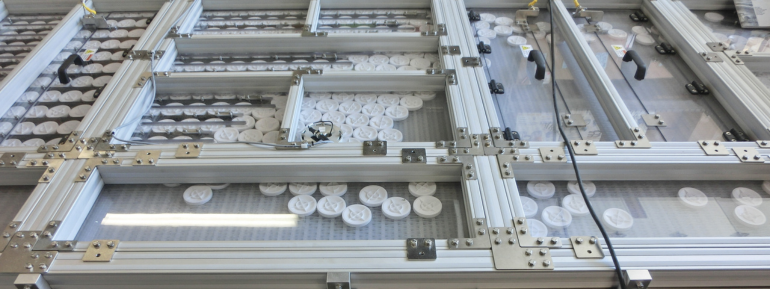

Conveyor Linear Feeder Systems:

Conveyor linear feeder systems come in many styles and are the most common choice among centrifugal feeders. They are easily configurable for maximum accumulation, transport at a high speed, and are quieter than other types of linear feeders. Conveyor systems are used frequently in packaging, automotive, and material handling.

Airveyor Inline Feeder Systems:

Airveyor inline feeder systems are an ideal solution if an elevation change is required. These feeder systems work at super-high speeds, can stretch for infinite lengths, and are gentle on parts. The negatives are noise produced by the blowers and a higher cost compared to other alternatives.

Gravity Track Linear Feeder Systems:

As you might suspect from the name, these linear feeder systems rely on gravity to feed parts rather than mechanical motion. Gravity Track systems are less expensive, produced less noise, and require no consumable parts or maintenance. What makes them challenging, however, is the need for the system to be designed at a higher elevation to allow for a down angle track. As a result, they’re more difficult for operators to access and maintain feeder tooling.

Does your organization have a part that would benefit from a new linear feeder system? Contact us today to learn more about how we can help.

April 17, 2017

Related Topics: Vibratory Feeders, Conveyors